Description

We have completely revised and redesigned this machine. State-of-the-art technology with SIEMENS S7-1200 control, wire breakage sensor and the latest servo motors .

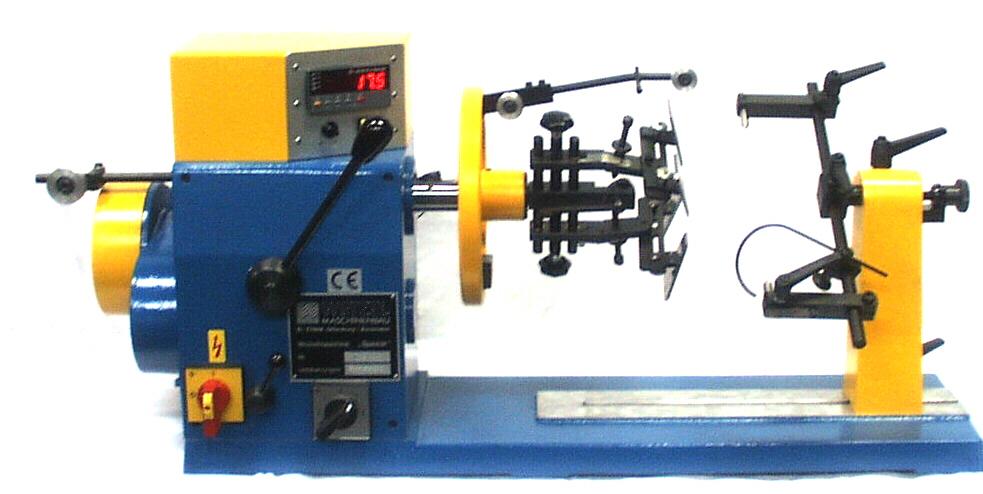

The “Special R” armature winding machine is a universal machine for winding armatures and coils of all kinds. Due to its easy operation and quick adjustability to different armature sizes, the machine is suitable for both individual winding and series winding of armatures.

The wire guide is easily and quickly adjusted to the armature diameter and the armature pack length, even for armatures with sloping grooves. The wire guide plates lie on the armature slot edges with spring pressure and hold the slot insulation in place. The wire guide plates are opened with a flick of the wrist and the armature is rotated further from slot to slot.

The armature carrier in the counterholder of the machine is designed for axial and radial adjustability. The axial adjustability is given by a fine adjustment so that the wire guide plates can be placed exactly on the armature slot edges. The different lengths of the anchor axles are adjusted between the tips of the anchor support. The anchors can be picked up with or without axis centering.

A sliding bracket covers the armature’s collector to prevent damage to the wire insulation when winding the armature.

The armature winding device is easily removable. Stator, form, magnet and transformer coils etc. can be wound by attaching various winding devices, face plates, winding mandrels and chucks.

The controller is informed of the speed, windings and direction of rotation you want to manufacture. Once the set number of turns has been reached, it is switched off automatically.

The counter is suitable for left and right rotation and therefore also suitable for left-handers. The control achieves a slow start and stop of the winding shaft and an exact number of windings. An interruption in the winding process can be resumed at any time. The drive is provided by the latest servo technology.